Bricks v/s Blocks for your house

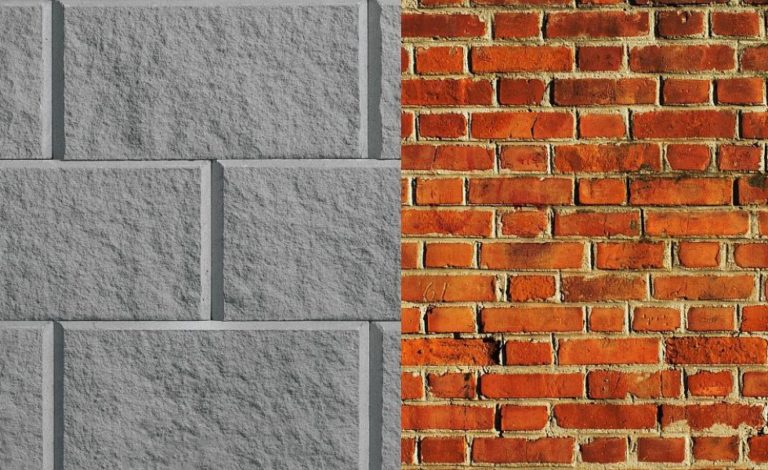

A brick is building material used to make walls, pavements and other elements in masonry construction (Wikipedia). They are the most used material in the construction process and many a times ignored product. Its only from recent times people have started giving attention to what type of brick could be used in building a house. Due to growing demand of modern architecture and changing mindsets, the walls have been changing from bricks to concrete bricks/ blocks and many variants of bricks.

A brick can be composed of clay-bearing soil, sand, lime, or other concrete materials. Bricks are produced in numerous classes, types, materials, and sizes which have been always varying with different region and time period. There are many variants of bricks available in market today, however we would be considering regular red bricks in this article.

Brick Manufacturing Process in brief:

- Winning- Excavating soil from agriculture fields or clay beds, transporting it to the brick moulding site and filter to remove any impurities like stones etc.

- Preparation– Adding water in the ratio of 1:2 and filtering the clay out of the soil. Adding fly ash, stone dust, coal powder, rice husk, etc depending upon availability.

- Shaping– Moulding either by hand or by machine using moulds. Machine moulding is reported better in terms of quality of bricks, i.e., compressive strength and uniformity.

- Drying– Open air, hot floor, chamber, tunnel, etc are the drying methods adopted in various parts of the world.

- Firing– Firing process consists of increasing the temperature of bricks progressively, holding it at a peak temperature (800 to 1100 degree Celsius) and then gradually cooling it.

- Sorting – Sorting into grades, e.g. firsts, seconds, soft (re burn) and sold.

Concrete Blocks Manufacturing Process in brief:

- Mixing – Adding required amounts of sand, gravel and cement into the bins and blending for several minutes added with water. Ad mixtures would also be added at this stage.

- Moulding – Pouring concrete mixture into the moulds and compaction by air or by hydraulic pressure.

- Curing – Standard blocks are usually cured at 66-74 degree celsius and light weight blocks at 77-85 degree celsius. Generally it takes 24 hours for whole curing cycle.

- Sorting – Sorting of blocks into cubes.

Let’s distinguish bricks and blocks on various parameters which might help you consider your choice for house construction

Strength

The biggest debate we face with clients is always about the strength f bricks vs blocks. Both brick and blocks are strong materials, but strength is affected by mortar used. According to properties of brick masonry, the average clay brick can withstand 2500 psi where as concrete blocks generally withstands 3000 psi.

Size

As we all know, blocks are generally equivalent to 4-6 clay bricks. Though we have different sizes of blocks and bricks available in the market, when it comes to size, generally clients prefer blocks due to convenience in transportation, storage, and labour expense.

Time Consumption

Does the size impact time taken to construct a wall? Yes it does. You would spend additional time and subjectively more labor cost and more consumption of mortar to construct when you use clay bricks.

Thermal Variability

Both Clay bricks and concrete blocks have high thermal mass. Comparitvely clay bricks would keep the interiors cooler. One would probably be comfortable with a fan instead of air conditioner.

Cost variation

As mentioned earlier one block would be equivalent generally utpo 4-6 bricks. It is definitely more expensive to build a wall considering both materials and labour using bricks compared to blocks.

Moisture resistance

Though not absolutely water proof, clay bricks are more durable. They generally resist penetration of water and for the same reason bricks are used for external walls. Moisture may eventually seep through joints and for the same reason brickwork is generally constructed with space separating from the internal leaf. Concrete blocks are porous materials and has to be treated, coated or covered to prevent from moisture seeping through.

Damage repair

We have all seen patches done block walls but not on bricks. Its easy to repair a wall or rectify a mistake on block constructed wall than brickwork wall which requires entire wall to be redone if damaged.

It’s a constant debate of using bricks vs blocks in a residential construction. Considering modern architectural designs usage of brick walls for external wall has increased due to aesthetic quality of clay bricks compared to blocks. Both concrete blocks and clay bricks have its own advantages and disadvantages. We request to consider the same and assess as per your requirement keeping in mind cost and time factor.

Thank you for reading this article.

Biblography:

https://www.materialtree.com/blog/Concrete-Blocks-Specification/

http://www.madehow.com/Volume-3/Concrete-Block.html

https://www.hunker.com/13401175/concrete-block-vs-brick

http://www.yourhome.gov.au/materials/brickwork-and-blockwork

Pictures:

https://dir.indiamart.com/nagpur/bricks.html

https://www.google.co.in/search?q=bricks&rlz=1C1RLNS_enIN695IN695&source=lnms&tbm=isch&sa=X&ved=0ahUKEwjCwKKAo4rbAhUNfH0KHVggAysQ_AUICigB&biw=1429&bih=677#imgrc=l4wPVhQ53udTBM:

http://www.freedomworks.org/content/house-acts-save-american-brick-industry

http://www.asanduffconstruction.com/tag/concrete-building-blocks-factory/

https://www.primal-state.de/icon-strength/

https://en.wikipedia.org/wiki/Brick

https://openclipart.org/detail/202784/time